YTEC provides a full range of semiconductor back-end OEM services.

Semiconductor OEM Service

LED OEM Service

RFID OEM Service

YTEC provides comprehensive semiconductor backend OEM services, including wafer testing, wafer grinding, sawing and IC pick & place, IC final testing, special substrate sawing, test program development, platform conversion, engineering support, drop shipping and other services, establishing a complementary and balanced diversified product line to meet various testing needs of customers, and to assist customers in quickly marketing ICs with highly competitive testing costs and testing energy.

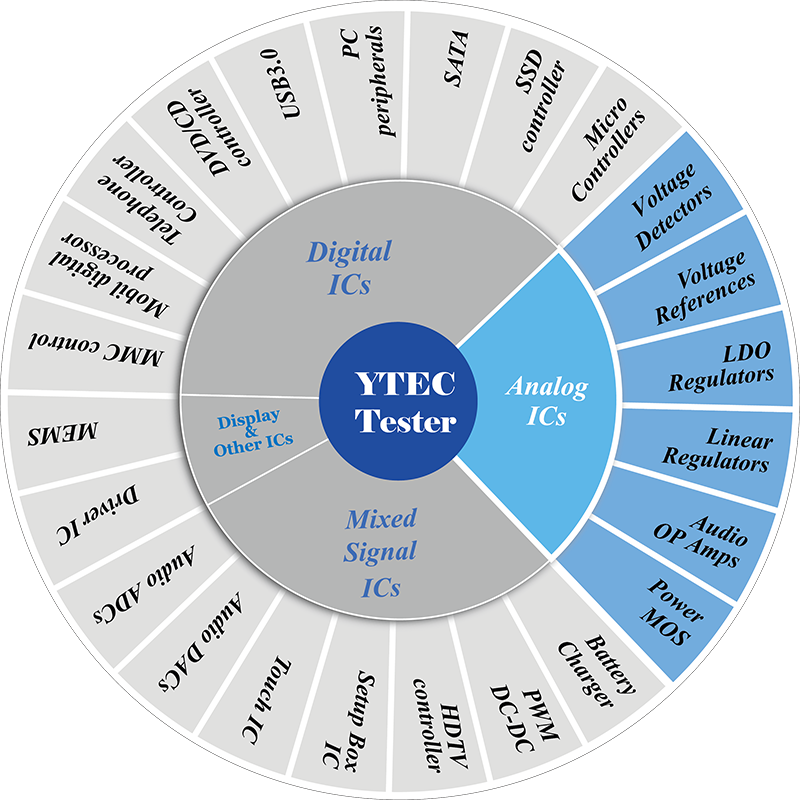

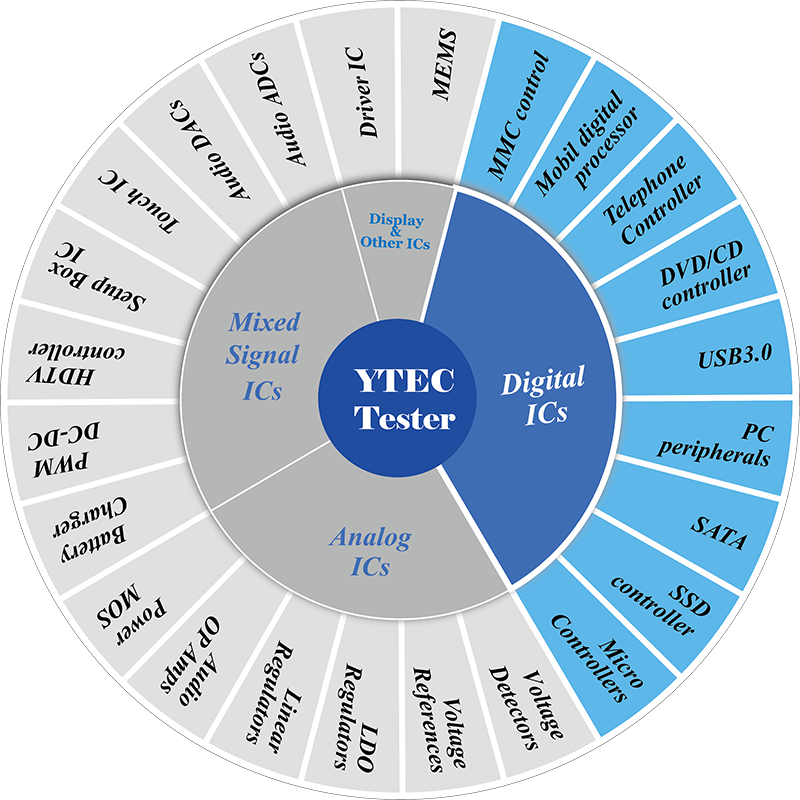

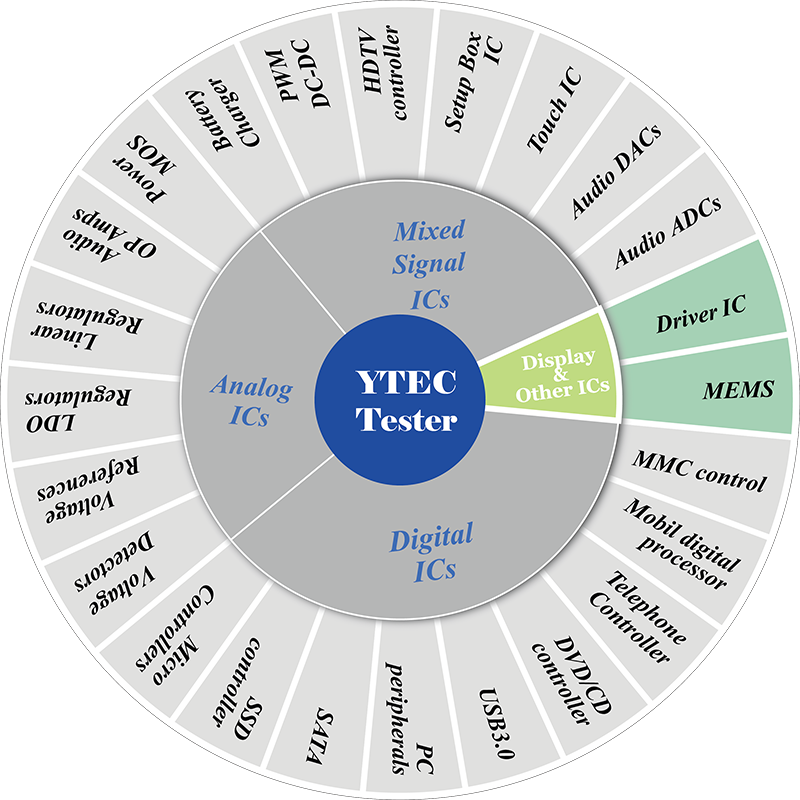

Test Product Types and terminal applications

The types of ICs that YTEC is capable of testing include PC peripherals, Logic, Mix-Signal, Non-volatile memory, MCU, USB, Analog power management IC, CIS image sensor detector, MEMS, RF communication product IC, LCD driver IC, IoT/3C IC, automotive IC, etc.

Analog IC

Digital IC

Mixed-Signal IC

Display & Other ICs

Service Process

Semiconductor OEM Service

01 . Wafer Testing

02 . Wafer Grinding, Sawing and IC Pick & Place

03 . IC Final Testing

04 . Special Substrate Sawing

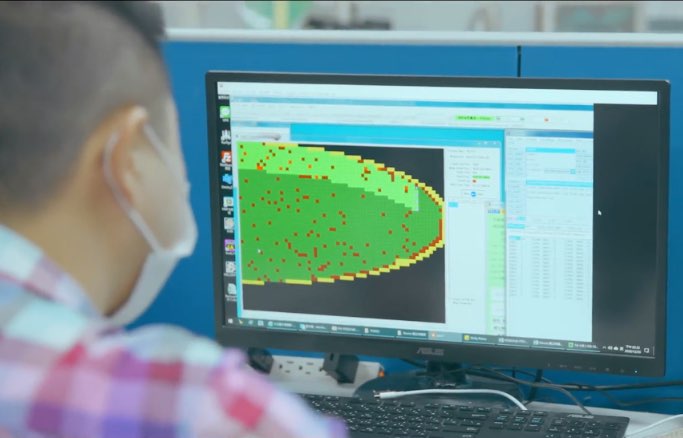

01 . Wafer Testing

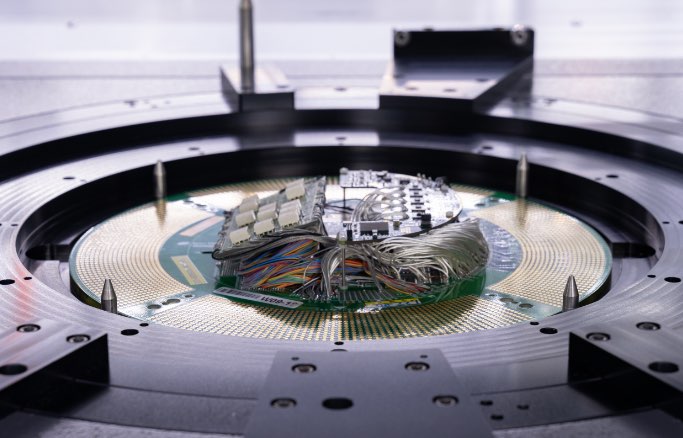

YETC plant located in the Science and Technology Headquarters of Science Park, Hsinchu Science Park, is capable of testing 6, 8, and 12-inch wafers. The service items include SOC / LCD Driver / CIS / RF and other products, and provide customers with high-quality test solutions.

| Function | MODEL | REMARK |

|---|---|---|

| Tester | YTEC S100 | Full function |

| YTEC V50 | Full function | |

| Yokogawa 6730 | LCD Driver | |

| Yokogawa 6731 | LCD Driver | |

| ADVANTEST ND4 | LCD Driver | |

| YTEC 100LCDD Gen.1 | LCD Driver | |

| YTEC 100LCDD Gen.3 | LCD Driver | |

| Prober | TSK UF190 | 6 ~8 inch wafer |

| TSK UF200 Serials | 6 ~8 inch wafer | |

| TSK UF3000 Serials | 8 ~12 inch wafer |

Process Flow

02 . Wafer Grinding, Sawing and IC Pick & Place

YTEC mainly provides 6”~12” wafer grinding, sawing and IC pick & place services at the Company's headquarters located on Keji Road.

| Function | MODEL | REMARK |

|---|---|---|

| Grinding | DISCO DGP8760+DFM2700 |

8 ~ 12 inch wafer Grinding+Dry polishing+In-Line Wafer Mounter |

| DISCO DGP8761 |

8 ~ 12 inch wafer Grinding+Dry polishing | |

| DISCO DFG8540 |

6 ~ 8 inch wafer | |

| Sawing | DISCO DFD6361 |

6 ~ 12 inch wafer on Dicing Frame |

| DISCO DFD6340 |

6 ~ 8 inch wafer on Dicing Frame | |

| AOI | MACHVISION AVI-350 |

6 ~ 8 inch wafer on Dicing Frame |

| TOPCON VI-4202 |

6 ~ 8 inch wafer on Dicing Frame | |

| HON. PRECISION In Tray AOI HT-1200Y |

2 ~ 4 inch Chip Tray | |

| Sorting | YTEC LS-serials |

6 ~8 inch wafer on Dicing Frame to 2 ~4 inch Chip Tray |

| EMTEC WCS-822 |

6 ~8 inch wafer on Dicing Frame to 2 ~4 inch Chip Tray | |

| YTEC IS-serials |

6 ~12 inch wafer on Dicing Frame to 2 ~4 inch Chip Tray |

Process Flow

03 . IC Final Testing

The Chuangxin plant located in Hsinchu Science Park, Chuangxun One Road, provides advanced test solutions such as Logic, Mix signal, Power, and RF. In addition YTEC has services related to program development, platform conversion, and engineering support capabilities. Final product testing types cover various types such as QFN, QFP, DFN, BGA, etc., and also provide assistance to customers with L/B, Socket, and Kit outsourcing operations to satisfy customers' needs.

| Function | MODEL | REMARK |

|---|---|---|

| Tester | YTEC S100 | Full function |

| YTEC V50 | Full function | |

| SEIKO EPSON Serials | SEIKO EPSON Serials | Tray |

| YTEC Serials | Tray | |

| YTEC Serials | Bowl Feeder | |

| ISMECA NY20 | Bowl Feeder |

Process Flow

04 . Special Substrate Sawing

The plant located in Puding provides special substrate cutting services at the Puding plant.

Process Flow

Test Program Development

Use the test platform conversion capabilities, with the flexibility and compatibility of independent research and development, to continuously create and provide diversified test solutions, greatly reduce the cost of test equipment, shorten the platform conversion and test time, so as to enhance the competitive advantage of customer costs.

Engineering Support

YTEC assists in the design of accessories and jig tools. The R&D team has the design capabilities of printed circuit board (PCB), Probe Card, Test Load Board, Test Interface (Docking) and assists in contracting, The development of customized key parts and accessories can improve the timeliness and speed of customer product testing in order to meet customer needs and quality.

Other Services

Data Management Platform:

- YTEC can provide customers with customized data and data feedback platform. Customers can choose to automatically send data to the designated location through the e-service platform or through a secure delivery mechanism.

- All types of data and form formats can be customized according to customer requirements.

- Production data will be stored in the Data Center of YTEC for more than 3 years, and can be stored for a longer time according to customer requirements.

Information Technology Service

- Data B2B Automation: OEM data of testing, grinding, sawing, pick & place can be sent to the customer through the network (e.g. FTP/sFTP) regularly based on time and site.

- Information Platform Service: YTEC provides an e-Service information platform, where customers can access the platform to download various information and data.

- Remote Connection: Can connect remotely and control the test equipment to perform engineering development and verification.

- Education and Training Platform: YTEC provides online education and training (e-Learning) to allow customers familiar with the use of the platform more quickly.